Build your kit according to plans – experiment AFTER it has flown - by David Cyr

My aviation partner and I built a Quickie Q2 over a period of 8+ years, with first flight in 1989. With over 150 hours on the aircraft, we sold the project to another Q2 enthusiast. We were extremely pleased with the way the aircraft performed and the way it flew, but it was sadly underutilized, so hopefully someone else will make more use of the project that taught us many skills and some important lessons.

One lesson we learned the hard way was to “build according to plans”; and not to get creative with “good ideas”. We had heard this many times from members on the Quickie Yahoo discussion forum, but of course we knew better…

The fuel is gravity-fed from a header tank located behind the instrument panel to the carburetor below the engine, resulting in a head of about 14 inches, which turned out to be marginal in terms of fuel pressure to adequately feed the engine. To improve the situation, an E.C. (engineering change) came along mid project that involved putting a forward-facing pressure tube on top of the fuselage right above, and entering the header tank. This “Pitot” pressure tube added sufficient pressure to the fuel system to ensure adequate fuel flow in a full-power climbing attitude. However, we felt this created other potential problems. The tube being on top of the aircraft was open to the rain, which meant possible contamination of the fuel with water. Also, in the event the plane ever flipped over on the ground, the gasoline would pour out the pressure tube, exacerbating an already significant event. So, our creative solution was to install the pressure tube under the fuselage and route the tube into the main tank, located under the occupants’ legs. Referring to the sketched diagram, you will see that the pressure tube ran into the fuel system at the top of the gasoline filler pipe. This solved both problems, so we thought! However, this caused another far more serious problem.

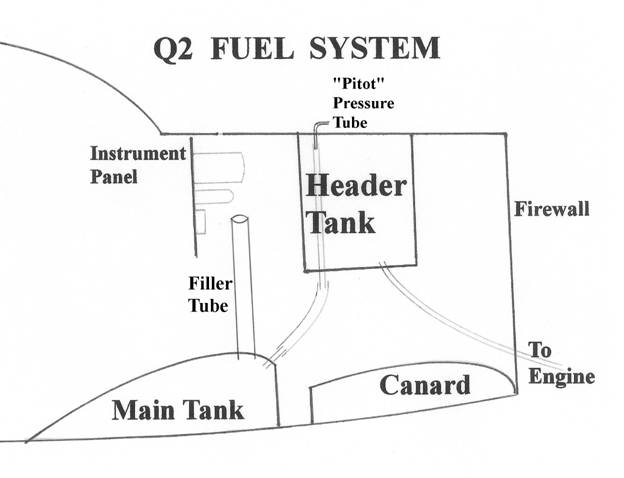

To understand what happened, I will explain the engineering change a little further; the way QAC (Quickie Aircraft Corporation) intended it be implemented. Referring to Diagram # 1, fuel is pumped into the filler tube that flows into the main tank. There is an electric pump to raise the fuel to the header tank that gravity feeds the engine (not shown). An overflow tube from the header tank to the main tank returns excess fuel to the main tank so the fuel pump can run continuously. The suggested E.C involved installing a forward-facing pressure tube (labelled “Pitot” Pressure Tube) that terminates inside the header tank, about in inch down inside the overflow tube so that fuel does not slosh out the pressure tube in turbulence or while taxiing.

Diagram # 1 - Engineering Change as Issued by Quickie Aircraft Corporation (QAC)

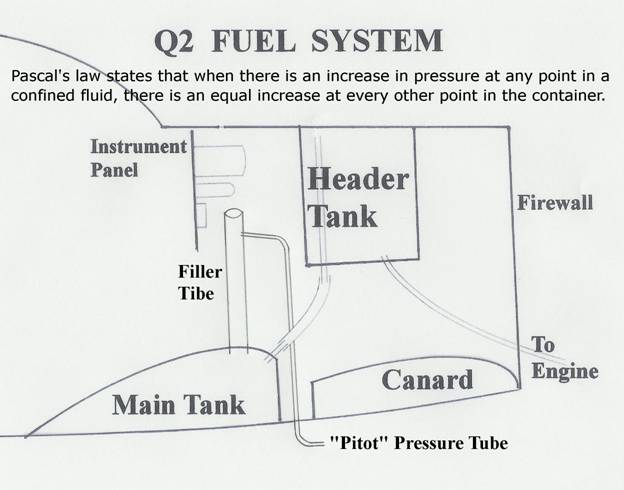

Now the solution to the problems with QAC’s E.C. (Refer to Diagram # 2): To prevent rain water entering the pressure tube, the “Pitot” tube was placed under the fuselage. Since Pascal taught us the pressure in the main tank would be transferred to the header tank, where we need the additional pressure, we decided to place the other end of the pressure tube at the upper end of the fuel filler pipe just below the fuel cap. This would ensure fuel would not spill if the aircraft was inverted. The aircraft flew like this for at least 15 hours without incident; and then the engine sputtered on take-off as I reached rotation speed. I immediately cut power and did a rather hurried stop at the end of the runway, taxied back to my parking spot and started experimenting. The engine wouldn’t continue running after a short run-up, so I disconnected the fuel line from the carburetor to see if fuel was flowing. Little, then none! We only had fuel flow when the fuel pump ran. What was going on!?!?!? A full header tank should have been more than adequate to feed the engine without the pump running, as was always the case during take-off and landing. The fuel pump was only required to top up the header tank.

Diagram # 2 – “Improved Creative Solution”

With this information, can you see the reason for our problem?

Up until that point, we had not filled the main tank to capacity since we were doing short flights and wanted to keep the weight to a minimum during the flight test period. (You can interpret “test period” as learning and adaptation on the part of the pilot more than aircraft testing.) Anyway, all went well until we filled the tank full. With a full tank, the gasoline in the main tank covered the bottom of the overflow tube that runs between main and header tanks. Since the overflow tube also allows air to replace fuel in the header tank as gasoline flows to the engine, the engine had to siphon gasoline up from the main tank; impossible, so no fuel flow!

Anyway, whether you understand my ramblings or not, you should do better than we did, and heed the warnings to build per plans. If you want to improve things, either discuss it with the designer or wait until you have the aircraft flying as designed, then start experimenting with your own creative solutions. Better still, be part of a discussion group and pick up improvements that other people have designed, and more importantly, tested! Things could have turned out a lot worse had it taken any longer for the fuel to run out.